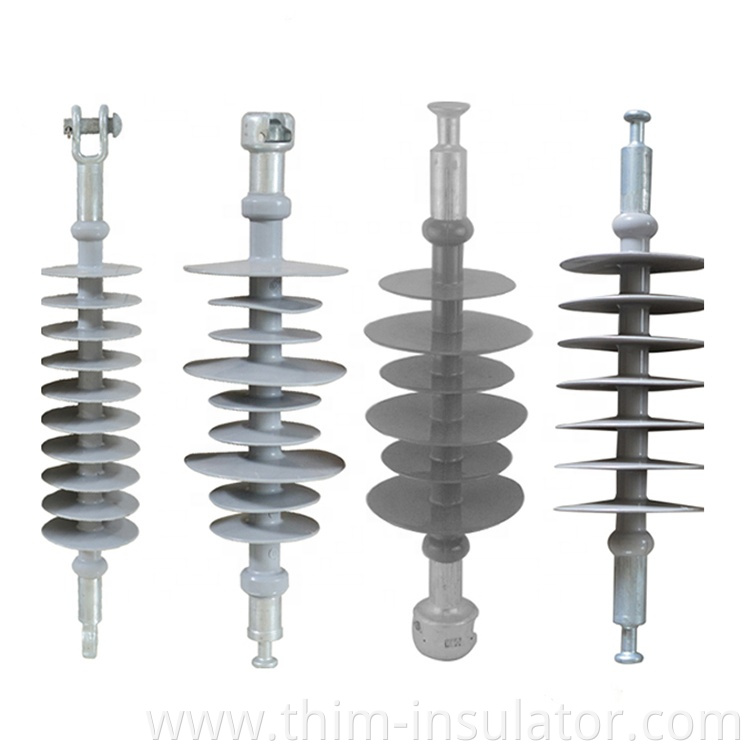

Electric Composite Suspension Insulator

$5≥100Piece/Pieces

| Payment Type: | L/C,T/T,D/P |

| Incoterm: | FOB,CFR,CIF,EXW,DDP |

| Min. Order: | 100 Piece/Pieces |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shanghai |

Select Language

$5≥100Piece/Pieces

| Payment Type: | L/C,T/T,D/P |

| Incoterm: | FOB,CFR,CIF,EXW,DDP |

| Min. Order: | 100 Piece/Pieces |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shanghai |

Place Of Origin: China

| Selling Units | : | Piece/Pieces |

The design and manufacture of composite insulators involve High-voltage, mechanical, chemical and other related knowledge. Generally speaking, the design of composite insulators is given according to the requirements of the electrical and mechanical properties of the insulator, and each component should be designed, selected and calculated separately. The results of design calculations should be combined with experimental measurements. The design of composite insulators includes: determination of insulator distance and insulation level, determination of creepage distance, mandrel design, shed material and structure selection, structural design of fittings, and pressure equalizing rings for insulators above 220kv. In the design and manufacture, the material selection of the shed sheath, the material selection of the mandrel and the selection of the bonding material should be carried out. These designs need to comprehensively consider the electrical and mechanical loads that composite insulators undertake in the operating environment, as well as the impact of environmental factors on insulator performance.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.