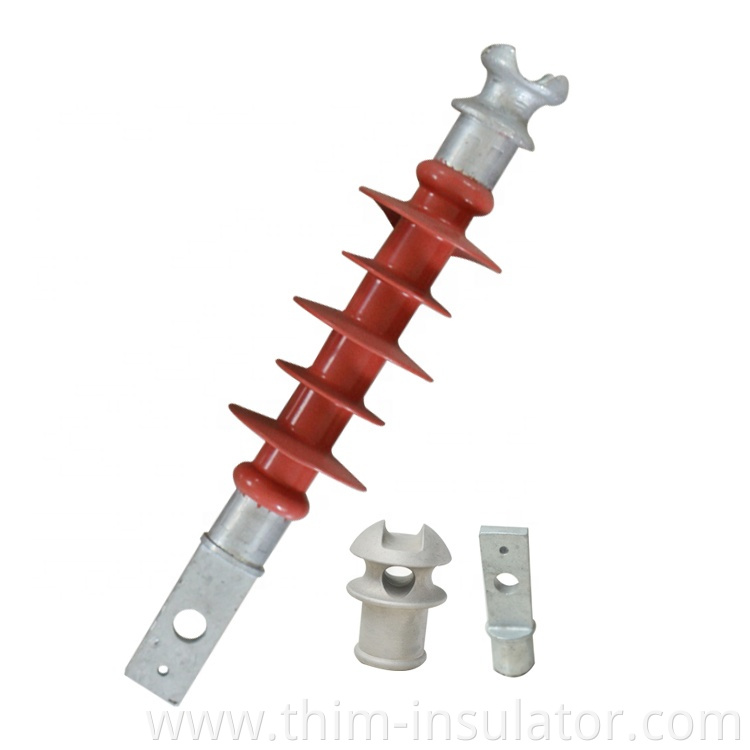

FRP Polymer Fiberglass Insulation Cross Arm Insulator

$15100-999 Others

$101000-4999 Others

$5≥5000Others

| Payment Type: | L/C,D/P,D/A,T/T,Paypal,MoneyGram |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shanghai |

Select Language

$15100-999 Others

$101000-4999 Others

$5≥5000Others

| Payment Type: | L/C,D/P,D/A,T/T,Paypal,MoneyGram |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shanghai |

Brand Name: THIM

Model Number: FS-35/5

Type: Insulator

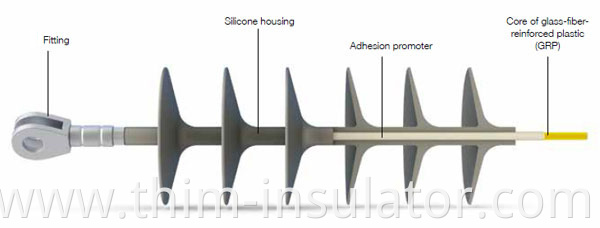

Material: Composite Polymer

Application: High Voltage

Product Name: High Resistance Bending Strength Composite Cross Arm Insulator FS-35/5

Color: Red or customized

Thickness: Customer Demands

Diameter: 5-180mm Insulator core rod(epoxy resin rod)

Voltage: 10kv -750kv silicone rubber insulator

Insulator Fittings: Ball, Socket, Tongue, Clevis, Flange and so on

Feature: Heat-Resistant, light weight, high mechanical strength, etc

Usage: Electric Power

OEM: Available

Sample: sample available

Place Of Origin: Jiangsu, China

Rated Voltage: 35KV

Tensile Strength: 5KN

| Selling Units | : | piece |

| Package Type | : | High Resistance Bending Strength Composite Cross Arm Insulator FS-35/5 cartons or customized |

| Type | Center distance of line groove and mounting hole (mm) | Arcing distance (mm) | Creepage distance (mm) | Full wave lighting impulse withstand voltage (peak) | Wet power frequency withstand voltage (valid value) | Line groove size R | Mounting size | Stable hole diameter ±0.5 | Center distance of mounting hole and stable hole a±1 |

| | | | | | | | Hole diameter d1 ±0.5/ Height h ≤ | | |

| FS-10/2.5 | 400 | 315 | 460 | 165 | 65 | 11 | 18/17 | 6.5 | 40 |

| FS-10/5 | 400 | 300 | 610 | 165 | 65 | 14 | 22/58 | 11 | 40 |

| FS-35/5 | 620 | 520 | 1080 | 290 | 130 | 14 | 22/58 | 11 | 40 |

| FS-110/5 | 1150 | 1030 | 3200 | 580 | 330 | 14 | 22/66 | 11 | 40 |

| FS-220/5 | 2215 | 2050 | 6300 | 1000 | 395 | 15 | 22/82 | 12 | 30 |

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.